The very recent lithography process which, in 2011, is in the pilot stage (i.e. before mass production) is called Extreme Ultra Violet (EUV) lithography. It is expected to be used for 22 nm technology (i.e. when the gate length is 22 nm). It uses electromagnetic waves at 13.5 nm. Any electromagnetic wave of wavelength in the range of 10 nm to 400 nm is called UV. The waves of 10 to 120 nm wavelength are called Extreme UV. These are generated using plasma sources. Since almost all materials absorb EUV, the EUV lithography must be done in vacuum. The mask and other optics would be using reflective method and not refractive (normal lens system) method. Another technique in research mode is X-ray lithography. Since X-rays have very short wavelengths (less than 1 nm), the diffraction limitations of normal lithography would not be present. Some of the difficulties faced are (a) it is difficult to bend and focus the X-rays and hence only 1X mask can be used and (b) secondary electrons generated by X-ray causes contrast issues. Since most dust particles will transmit X rays, particle contamination is less of an issue. Interestingly, X ray lithography is applied in micro electro mechanical system (MEMS) fabrication. A problem common to all next generation techniques is that they are very expensive.

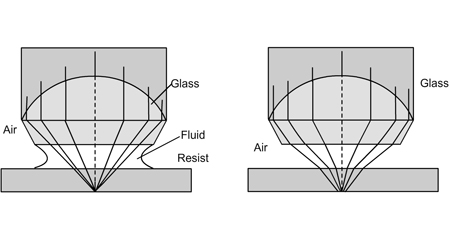

Immersion Lithography: In the latest commercial lithographic instruments (as of 2012), a technique called liquid immersion lithography is used. In this, a fluid such as water (or preferably with high refractive index) is introduced between the wafer and the lens, as shown in Fig. 2.20. If the refractive index of the fluid matches that of the lens, (and assuming that the refractive index of the photoresist is similar to that of the lens) then the images formed at the bottom of the photo resist will be with high resolution. Comparatively, if the fluid were not present, the light path will be different and the resolution will be poorer. Even if the refractive index of the fluid is not the same as that of the lens, if it is higher than that of air, it will enhance the resolution. The resolution enhancement obtainable through immersion lithography is about 30 to 40% and an increased depth of focus (40 to 70%) can also be achieved.

Fig 2.20. Schematic of immersion lithography

The requirements of the fluid are that it must be compatible with the photo resist and the lens and that it should not absorb the light used (< 5% absorption). High purity water satisfies these requirements. Its refractive index is 1.47 and it can be doped with sulfates or phosphates to increase the refractive index slightly. Commercially, water is continuously circulated between the wafer and the lens, and is maintained at a constant temperature since the refractive index can change with temperature. Care must be taken to ensure that it is particle free and bubble free, that it is removed after exposure, and that leaching from the photo resist is minimal.

Summary: To summarize, in the lithographic section in the manufacturing line, depth of focus is an important parameter for the production and this can be improved by CMP. Alignment is another important parameter and alignment masks are used for aligning the current level to the previous level. One should also be aware of the issue of partial field and be able to optimize the location of fields to obtain the maximum number of good chips. Immersion lithography can extend the use of current light sources by one generation. EUV lithography seems to be an emerging technique which may be used in the industry in the near future while X-ray lithography is still in research stage now. We will see the details of the deposition techniques in the next chapter.

|