Electromigration: When current is passing through a conductor, the electrons move from one end to the other end. They transfer some of their momentum to the metal atoms and gradually the metal atoms also move. This is called electromigration. This phenomenon is not of much importance when the current densities are low. In IC chip the current densities are very high and electromigration can cause failure of a circuit.

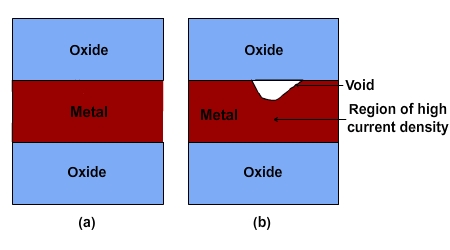

Fig 9.4 Schematic of electromigration causing failure. (a) Early stages. Wire occupies the entire space and the current goes through the metal. Current density is moderate (b) Void formation leads to decreased area available for conduction and increased current density. Acceleration of failure.

In the beginning, the metal would fill the space between the insulators and the current density would be at a certain level (Fig 9.4a). If sufficient atoms move due to electromigration, then a small void will form. Now the all current has to go through the metal and hence near the void region, the current density will increase. The electrical resistance of the metal line is also higher now, because the electrical resistance is inversely proportional to the cross sectional area. This results in larger heat release and hence higher local temperature. At higher temperatures, the metal atom diffusivity is higher, which makes it easier to ‘push’ the atoms. The increased current density and higher temperature accelerates the formation of voids and finally results in the circuit failure.

The extent of electromigration movement depends on the nature of the material. For example, materials such as copper, tungsten and gold have good electro migration resistance. We must note the difference between electrical resistance and electro migration resistance clearly. Electrical resistance indicates the resistance to movements of electrons. We want good electrical conductors (i.e. low electrical resistance). At the same time, we want materials which have high electro migration resistance.

If the electro migration resistance is poor, then after many hours of operation, the resistance of one or few wires will increase dramatically. It can lead to the failure of the chip. These types of failures, where the chip originally functions well and after few months of operation fails, are called “reliability issues”. This means that the chip appears to be good during testing in the fab, but it is not reliable and after sometime it can fail.

Aluminum has low electromigration resistance. To enhance its electromigration resistance, usually a small amount of Cu is added during the deposition of Al. Similarly, a small amount of Si is also added to Al. This is because Si has the tendency to dissolve into aluminum and the silicon in the insulator (silicon dioxide) may diffuse into aluminum. If the aluminum is already saturated with silicon, then further dissolution of Si in Al will not be possible. Thus, both Si and Cu are added in small quantities (1% for example) in the aluminum lines to minimize silicon dissolution and electromigration, respectively. Tungsten has a good electromigration resistance and hence the vias or contacts made of tungsten are quite immune to this issue.

The average time for failure, which is called MTF or mean time to fail, depends on the current density and the temperature. Usually if the wires are made with large grains, that is large crystals then it will not be easy to break the wire. If the size and the arrangement (that is the orientation of the grains) are good then the electro migration resistance will be high and the chip will not fail easily.

In order to test whether a material or chip will function for a long time without failure, frequently the chip is tested at high temperature. This is called high temperature operation test or HTOT. Sometimes the chip is also tested at a high temperature and high humidity. This is called highly accelerated stress test or HAST. Hence in every batch few chips will be tested using this to understand whether the chips made during those processes are prone to failure in the medium term.

The length of the metal line and the current density passing through that determine the MTF. The minimum value of the product of length and current density (L * j) needed for electromigration to cause catastrophic failure is called Blech product, named after I.A. Blech, who proposed it first. The higher the current density or longer the line, more the chance of failure by electromigration. For a given current density and material choice (Cu or Al), the critical length (minimum length) above which electromigration can cause failure is called Blech length.

|